When I was 11 my mom signed me up for sewing lessons with her friend, a professional seamstress and tailor. It was summer, and knowing now what it is like to have kids hanging around the house all day, I’m sure it was a device to keep me busy. That, and I was fond of using her sewing machine to try to make things, and I know I asked for help about every five minutes. I made an outfit at my lessons — shorts and a camp shirt. I’m impressed in retrospect. No way I’d try something that hard now.

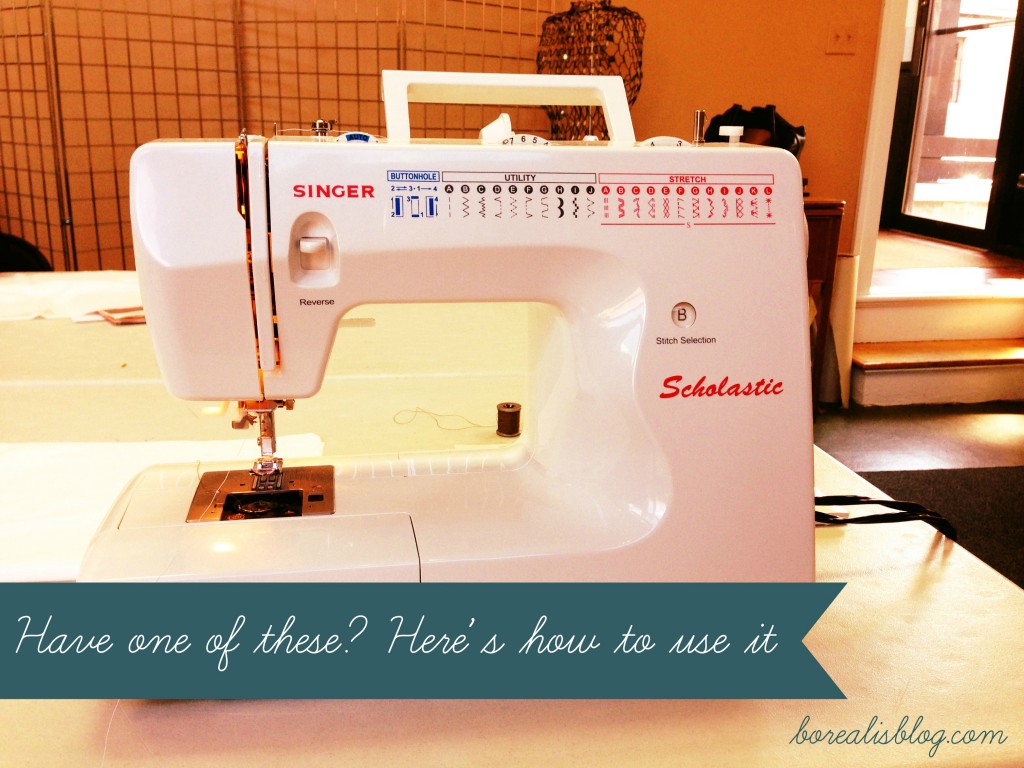

Fast-forward twenty-plus years and I have my own machine, a Singer just like my mom’s. It threads in exactly the same way too, ensuring that I never had to crack the manual. I plugged it in, wound a bobbin, and started to sew (straight lines only, as we’ve discussed before). This time though, my mom isn’t here to help me.

So after a few years of infrequent but ambitious use, trail and error, and plenty of machine and thread jams, I finally enrolled myself in a class about how to use your own machine — how to troubleshoot and clean it, what all those doodads that came with it are for, and what can it actually do (besides sew a straight-ish line).

I hauled my machine and its doodads to Treadle Yard Goods on Grand Avenue in St. Paul, known to many as the best fabric store around. For three hours, myself and two other women got specific, one-on-one help using our machines by a professional sewist. She even read my manual for me, and then told me what was in it. All of that for $35.

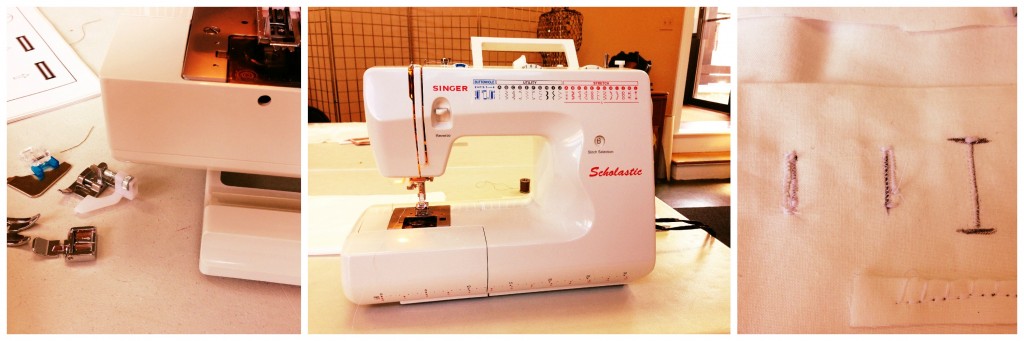

I learned things and tried things too — like buttonholes (!!), pictured above on the right. I discovered I have a zipper foot, a buttonhole foot, and a foot that makes invisible tailor hems (I forgot technical name already). The last was my favorite discovery. Very cool.

Here are my takeaways, for all of my fellow sewing-machine-owning, manual-avoiding, straight-line-only sewists:

- Your sewing machine will jam. Even frequently and for no apparent purpose. This is not because you don’t know how to use it. It happens to everyone. Feel better. It is not you. (Worth the price of admission right there.)

- If it jams, try these things, in this order, testing in between to see if it resolved the problem: rethread machine, change your thread, change your needle.

- Here’s how to understand tension: if your top thread is coming through to the bottom (you can see the loops), your top tension is too loose. If your bottom thread is coming through to the top, the top tension is too tight. We had different colors of top and bottom thread to test this out, and discovered that on my machine “auto” was a little too tight. Do not attempt to adjust the bottom/bobbin tension.

- You need to clean your machine, preferably after every 8 hours of sewing. There’s a little brush in the doodad bag for doing this. A can of pressurized air works too. Have it cleaned and tuned professionally every 2-3 years.

- Do not sew over pins. Not only is this dangerous and will break your needles, the impact can throw off the timing of the machine and you may have to have it reset. I had no idea; I sew over pins all the time. If you accidentally hit a pin, replace your needle, even if it doesn’t look damaged.

- When threading your machine, make sure presser foot is up, otherwise there is too much pressure to thread it properly.

- When manually moving needle (using that wheel on the right side), only move it forward, not backward. Again, no clue!

- I mentioned that I only sew straight lines and even then I have trouble. Her trick: put a rubber band around the bottom of your machine as a guide. Genius. Who can see those tiny lines near the feed dogs? (See how I used my new knowledge there? Feed dogs are the jagged edge metal things that move your fabric along when you sew.)

- Our teacher likes Schmetz universal needles the best. For almost any project using cotton, a 12 or 14 size will work. Use sharp needles for microfibers and ball points for knits. (I had no idea these things existed!) She also prefers Gutermann poly thread.

- If you are buying a machine for the first time, try to get a refurbished old one, the heavier the better, because then it is likely made of metal. Really and truly, our instructor said, they don’t make them like they used to. Plastic parts wear out; metal ones do not.

I definitely feel more confident in using and maintaining my machine now, and I’d recommend taking the class. It was really great to have someone help me with my actual machine.

Treadle has all kinds of classes throughout the year, including classes for kids and some on a summer-camp schedule. I think I’ll sign up for the zipper class next (why is that so scary!?), and then maybe the cushion class. I have had the fabric for the window seat in my office for more than seven years!

If you go

Treadle Yard Goods is on the corner of Grand Avenue and Hamline Avenue in St. Paul.

Check out the course schedule online, but you’ll have to call or stop in to register. Do yourself a favor and stop in if you’ve never been there, but be prepared — you may leave with far more than your class registration.

I especially like the $35 fee to have the instructor read the manual for you and tell you what it says…I need that for my car! ha ha Oh, and I’m married to the salesman.